HOME / 초저온응용장치 / 초저온저장탱크 /Chart VS Series

Chart VS Series

CHART PERMA-CYL 소형 초저온 저장탱크(1000L~2000L)

(주)두진은 CHART Industries inc의 공식에이전트로서 지난 30여년 동안 초저온 액화가스 탱크분야의 선두를 지켜온 CHART사의 액체질소, 액체산소, 액화수소, 액체아르곤, 탄산가스, LNG 등을 저장할 수 있는 초저온 벌크 탱크들을 공급해 왔습니다.

Chart 초저온 저장탱크는 세계적인 품질과 신뢰성으로 반도체, 화학, 바이오, 제약, 병원 등의 우수한 성능으로 각광받으며 1990년대 이후 국내 초창기 초저온 저장탱크 시장을 이끌어오며 현재까지도 많은 고객에게 각광받고 있습니다.

Chart VS Series 초저온 저장탱크

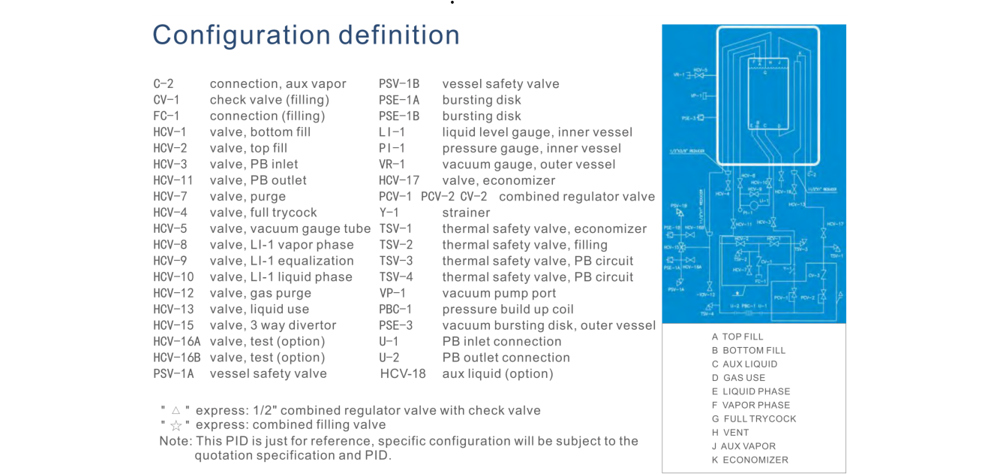

초저온 저장탱크는 이중구조의 내조와 외조로 구성되며 내조는 SUS304이상의 재질로 초저온(영하 50℃이하) 액화가스를 저장할 수 있도록 설계되어 있습니다.

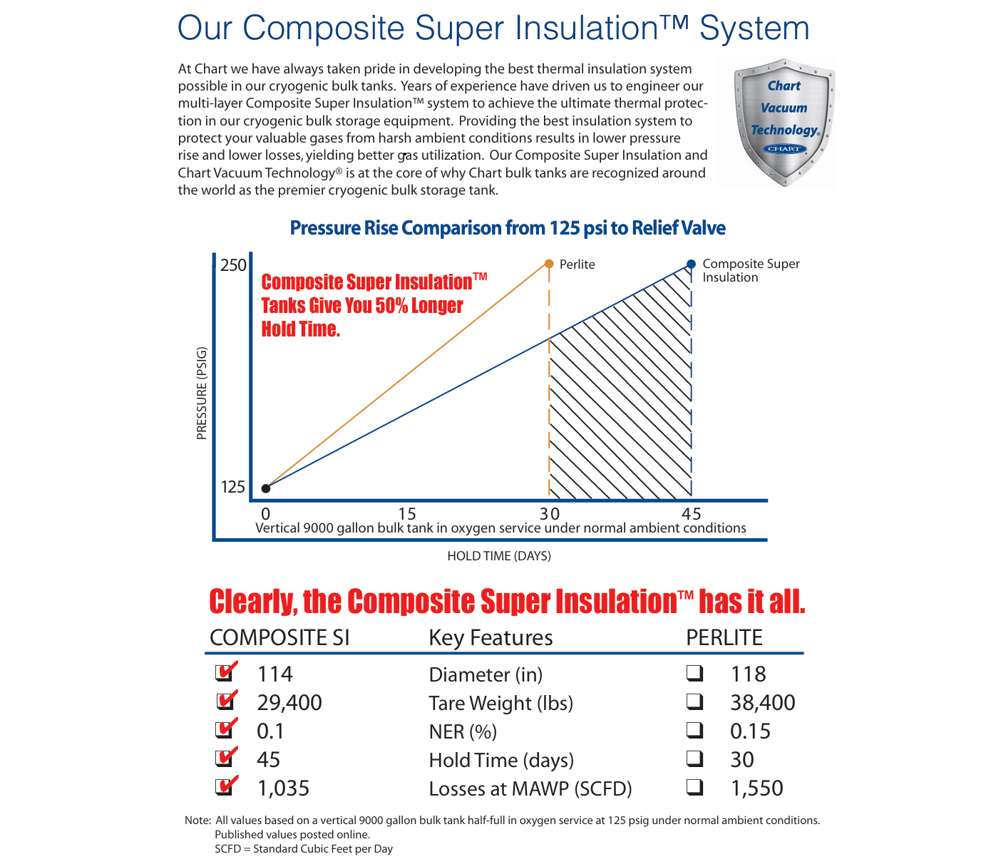

외조는 내조를 보호하며, 내조와 외조 사이는 극저온용 MLI(Multi Layer Super Insulation) 단열재를 적용 하고 0.01Torr 이하의 진공도를 유지합니다. CHART 저장탱크의 단열방식은 Perite Type, MLI Type으로 나뉩니다. CHART의 MLI TYPE TANK는 진공 및 단열성능의 강점을 내세워 기화손실을 현저하게 감소시켜 액화가스 장기보관에 있어 안전하고 우수한 단열성능을 자랑합니다.

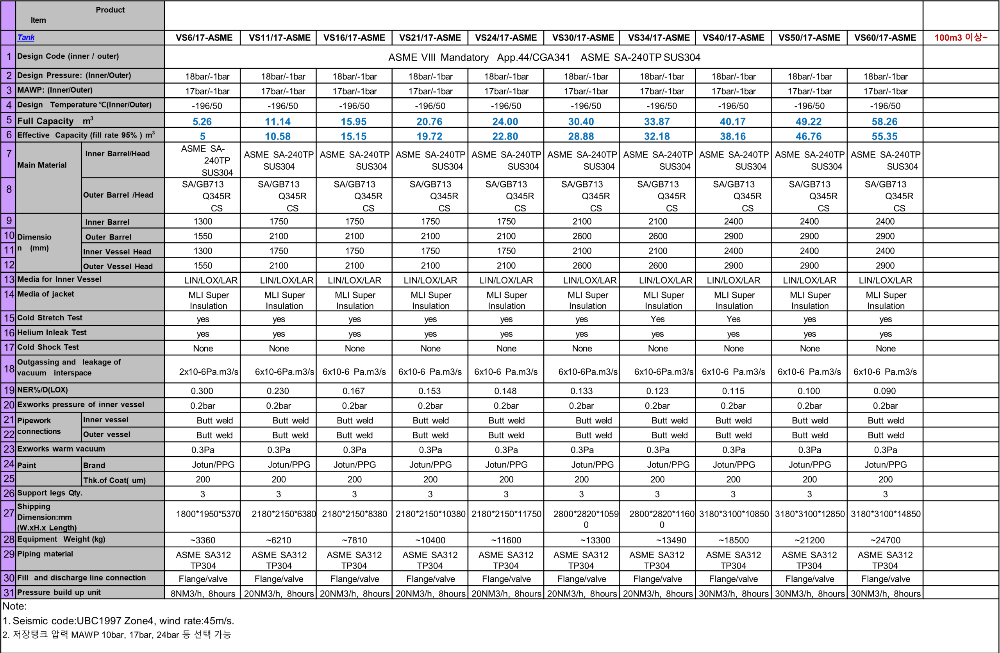

CHART 초저온 저장탱크는 효율적인 생산과 비용, 납기단축을 위해 표준화 제품을 유체, 사용량, 압력 등에 따라 구성합니다.

또한, 옵션을 통해 고객 요구 사항을 충족하며 커스터마이징이 가능합니다.

외조는 내조를 보호하며, 내조와 외조 사이는 극저온용 MLI(Multi Layer Super Insulation) 단열재를 적용 하고 0.01Torr 이하의 진공도를 유지합니다. CHART 저장탱크의 단열방식은 Perite Type, MLI Type으로 나뉩니다. CHART의 MLI TYPE TANK는 진공 및 단열성능의 강점을 내세워 기화손실을 현저하게 감소시켜 액화가스 장기보관에 있어 안전하고 우수한 단열성능을 자랑합니다.

CHART 초저온 저장탱크는 효율적인 생산과 비용, 납기단축을 위해 표준화 제품을 유체, 사용량, 압력 등에 따라 구성합니다.

또한, 옵션을 통해 고객 요구 사항을 충족하며 커스터마이징이 가능합니다.

Superior Design & Engineering

- Modular piping systems combine high performance, durability and low maintenance

- A reduced number of joints minimizes the risk of external leaks and facilitates simplified installation

- Easy access to control valves and instrumentation

- A comprehensive range of safety features afford maximum protection to operators and equipment

- Meet seismic requirements

- Engineered, manufactured and tested in accordance with all major international design codes and associated regional requirements

- Unrivaled engineering and manufacturing capacity

- World class facilities strategically located in centers of demand

- Dedicated range for carbon dioxide (CO2)

* a smaller capacity 900 US gallon (3,400 liter) capacity tank is available as standard from our European facilities and a 792 US gallon (3,000 liter) capacity tank is built in India.

- A reduced number of joints minimizes the risk of external leaks and facilitates simplified installation

- Easy access to control valves and instrumentation

- A comprehensive range of safety features afford maximum protection to operators and equipment

- Meet seismic requirements

- Engineered, manufactured and tested in accordance with all major international design codes and associated regional requirements

- Unrivaled engineering and manufacturing capacity

- World class facilities strategically located in centers of demand

- Dedicated range for carbon dioxide (CO2)

* a smaller capacity 900 US gallon (3,400 liter) capacity tank is available as standard from our European facilities and a 792 US gallon (3,000 liter) capacity tank is built in India.

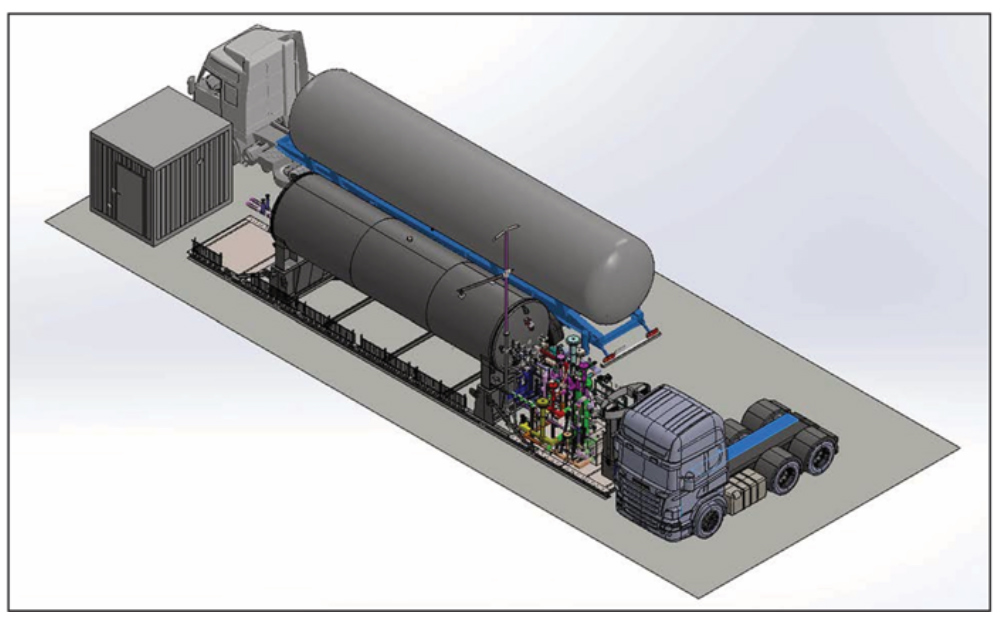

VS Series 횡형 저장탱크

■ 모든 요구 사항을 충족할 수 있도록 사전 설계된 옵션과 표준 기능을 갖추고 있음

■ ASME 코드에 맞게 설계되었으며 175 및 250 psig(12및 17 barg)로 표준으로 제공

■ 복합 단열 시스템은 높은 단열 성능과 긴 수명으로 교체 주기 비용 절감

■ 경량 설계를 통해 설치 비용 절감

Siphon Storage Tank for Cryogenic Pump

Chart's in-house developed siphon tank provides superior economic and reliable performance. Developed from our 'tank to pump1 system, which is widely used for loading gas to high pressure gas cylinder, it provides significant improvements on the low efficiency and high failure rate of traditional tanks. By integrating several innovative technologies it improves cryogenic pump performance with reductions in product loss, blockage and cavitation and also enables a fast pump start.

Product advantages

■ Pump start in 3 minutes or less

■ Easy to operate, reliable system

■ Higherthroughput of cryogenic liquid

■ Low pressure pump start (10psi or less)

■ Reduced liquid loss

■ Extended pump life

■ Suitable for connecting two cryogenic pumps

■ Suitable for all cryogenic pumps

■ Pump start in 3 minutes or less

■ Easy to operate, reliable system

■ Higherthroughput of cryogenic liquid

■ Low pressure pump start (10psi or less)

■ Reduced liquid loss

■ Extended pump life

■ Suitable for connecting two cryogenic pumps

■ Suitable for all cryogenic pumps

LH2 액화수소 저장탱크

Engineered Bulk Storage for Liquid Hydrogen Chart’s proven hydrogen experience and expertise gives you the assurance of meeting the most stringent code and measurement standards. Our engineered bulk storage solutions substantially reduce commissioning, compliance and safety risks. Chart designs, constructs and tests all of our equipment to meet your site-specific regulations as well as NFPA, ASME, PED and other local codes and regulations for each geography.

• Chart is the leader with 50+ years of experience in design, manufacture, test and assembly of liquid hydrogen storage equipment in our global facilities

• FCEV fuel stations, FC forklift fueling, liquefaction, aerospace and industrial applications

• More than 800 LH2 bulk tanks built

• Complete line of liquid hydrogen storage tanks – Project references up to 172,000 US gallons (650 m3 )

• Engineering expertise for unique app

• Chart is the leader with 50+ years of experience in design, manufacture, test and assembly of liquid hydrogen storage equipment in our global facilities

• FCEV fuel stations, FC forklift fueling, liquefaction, aerospace and industrial applications

• More than 800 LH2 bulk tanks built

• Complete line of liquid hydrogen storage tanks – Project references up to 172,000 US gallons (650 m3 )

• Engineering expertise for unique app

Integrated Solutions Brazed Aluminum Heat Exchangers (BAHX)

• LH2 fueling station development for FCEVs

• Liquefier product developments

• Integrated vaporization, compression and controls for trailer filling operations

• Modular designs for reduced installation costs

• On-board liquid fuel tanks for trucks, buses, etc.

• Mobile and containerized fuel stations and supply systems

• 25+ years of experience providing LNG stations

• LH2 fueling station development for FCEVs

• Liquefier product developments

• Integrated vaporization, compression and controls for trailer filling operations

• Modular designs for reduced installation costs

• On-board liquid fuel tanks for trucks, buses, etc.

• Mobile and containerized fuel stations and supply systems

• 25+ years of experience providing LNG stations